In this blog, we’ll introduce you to the Cubitron 3 family of products recently released by 3M that feature 3M precision-shaped ceramic grain, which cuts even faster and lasts even longer than CubitronTM II products.

Where There’s a Need, 3M Sees a Challenge

As industry requirements and expectations evolve, so do the leading innovators’ appetites for meeting them. Cubitron 3 was launched in direct response to evolving demands for better productivity, improved worker safety, and greater sustainability. 3M’s latest advancements in abrasive wheel technologies make grinding and cut-off wheels work even faster and last even longer than their previous best performing range.

The 3M Cubitron 3 products outperform the previous generation so impressively, the company is completely replacing the CubitronTM II offering to maximize simplicity and value to customers. With no change in list price, customers will now benefit from a wider product choice, better performance, and optimized sustainability with the new product offering.

Reshaping the Way Work Gets Done

To understand how 3M’s latest developments are revolutionizing grinding and cutting wheel performance, it’s important to understand how the technology has evolved over the years:

First Generation: Conventional Ceramic Abrasive

Conventional ceramic abrasive grain tends to “plow” through metal, causing heat to build up in the workpiece and abrasive, resulting in a slower cut and shorter abrasive life.

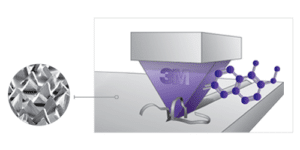

Second Generation: 3M Precision Shaped Grain

3M pioneered the first precision-shaped grain using 3M microreplication technology to form consistent sharp peaks that easily “slice” through metal instead of “plowing.” These abrasives cut cooler and faster, and lasted longer, than conventional abrasive grain.

3rd Generation: The latest 3M Precision-Shaped Grain

3rd Generation: The latest 3M Precision-Shaped Grain

3M has now re-engineered precision-shaped ceramic triangular grain using proprietary breakthroughs in molecular bonding technology.

Sustainability Matters to 3M Abrasives

3M is a founding member of the SEAM abrasives manufacturers program and aligns to the world’s highest standards of quality, safety and performance in a sustainable environment. When you buy from the SEAM value chain, you are helping to build a sustainable future for our industry, for people, and for the planet.

3M commits to transparency, accountability, innovation and progress. As a customer buying from the SEAM value chain, you are helping to build a sustainable future for your team, your community, and future generations.

Take the 3M Cubitron 3 Challenge

Take the 3M Cubitron 3 Challenge

Curious how the CubitronTM 3 would positively impact the speed and productivity of your team? We’re so confident in its performance that we’ve partnered with 3M to offer you a free trial of these high-quality abrasives to test in your work environment. Prepare to be impressed. Contact your account manager or visit your nearest Agilix branch to take the challenge today!

3rd Generation: The latest 3M Precision-Shaped Grain

3rd Generation: The latest 3M Precision-Shaped Grain Take the 3M Cubitron 3 Challenge

Take the 3M Cubitron 3 Challenge