Your industrial equipment represents a significant investment in ensuring uptime and operational efficiency. When it fails, industrial equipment repair can be a cost-effective alternative to replacement. That’s why Agilix Solutions offers comprehensive remanufacturing and repair services to help you get back to productivity without breaking the bank.

In this article, we’ll detail how Agilix Solutions helps you save the expense of a total replacement by repairing your used equipment or returning it to a like-new condition with remanufacturing services.

Industrial Equipment Eligible for Remanufacturing & Repair

Customers are often surprised by the variety of products eligible for repair or remanufacture, and the catalog of brand names we serve. Here’s just a small sampling of the products eligible for service through your local Agilix Solutions branch:

- Variable Frequency Drives (VFDs)

- Programmable Logic Controllers (PLCs)

- Human Machine Interfaces (HMIs)

- Printed Circuit Boards

- Feedback Components (tachometers, resolvers, encoders)

- Instruments & Metering Devices

- Terminals (CRTs)

- Power Supplies

- Motors

- Gearboxes

- Pumps

Agilix handles motor, pump, and gearbox repairs locally with 48-hour turnaround options to get you back up and running quickly. We ship electronic components out for remanufacturing in ISO-certified remanufacturing facilities. Those products are then returned to customers with a new 12-, 18-, or 24-month warranty for the entire unit.

You can access a complete list of manufacturers for our most commonly repaired products on our website.

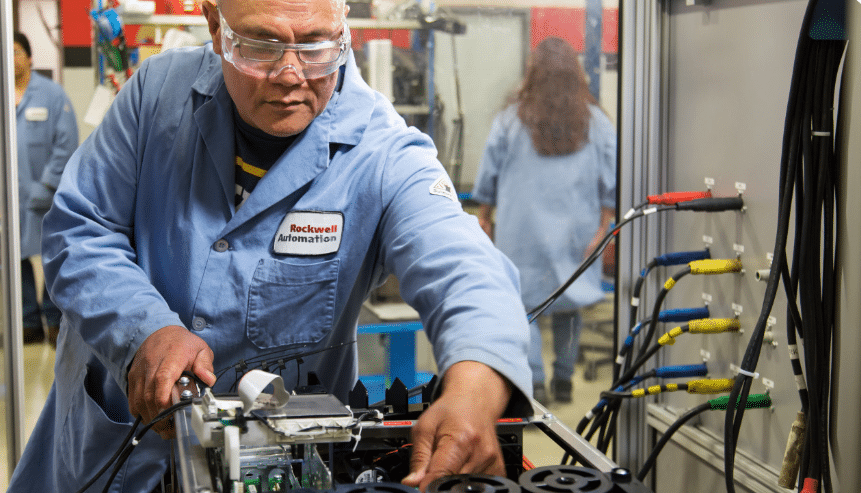

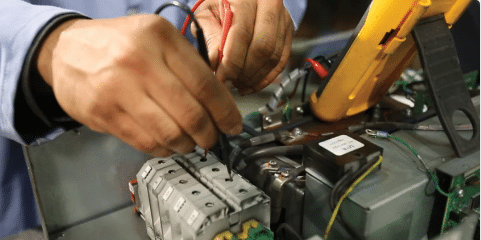

Rockwell Automation Standards for Allen-Bradley Remanufacturing

For Allen-Bradley products, Rockwell Automation follows a strict seven-step process using their ISO-certified remanufacturing facilities. Rockwell Automation upgrades your Allen-Bradley equipment to the latest proprietary revisions and enhancements, restoring it to original manufacturer specifications. They replace failed or marginal components with engineered specified parts, without substitutions. Rockwell Automation also commits to dynamic and environmental testing that goes above and beyond to weed out intermittent failures. Every remanufactured part is run through the same tests and held to the same standards as newly assembled products.

Repair+ Service Agreements Streamline Your Repair Process with a Single Contract

Agilix Solutions is Your Partner in Repair & Remanufacturing

Repair and remanufacturing extend the life of your equipment and free up your maintenance personnel for other priorities with Agilix Solutions. Agilix Solutions helps you maintain high-performing operations at budget-friendly prices. Reach out to your Account Manager, or call your nearest Agilix branch to learn more.