Corrosion is the enemy of longevity for mechanical equipment. And in food and beverage production and processing, the threat of corrosion is everywhere. As a result, manufacturers in these environments typically go one of two ways when investing in production equipment: products with a protective coating like paint, or products made from stainless steel.

Both have their limitations. Painting an aluminum surface simply adds a layer of protection that lays across the aluminum substrate. The paint doesn’t permanently bond to the aluminum, so it’s easily removed if it’s bumped or scratched. What can start as a small blemish in the painted coating can quickly turn into a much larger exposure under washdown conditions, as additional paint is chipped away.

Stainless steel construction is a much better alternative to aluminum covered with a surface coating. It doesn’t require harsh chemicals to clean and decreases the odds of leaks, rust, and corrosion. For those reasons, stainless steel has enjoyed a long reign as the material of choice in environments with high exposure to corrosive materials.

But it’s an expensive option. Installing gear boxes made of 300 series stainless steel, which is frequently used in food and beverage settings, throughout your facility can be a significant investment. Stainless steel also doesn’t dissipate heat as quickly as aluminum. Of course, this creates a safety hazard for employees. But heat is also a primary factor in motor wear. So stainless steel gear boxes face their own vulnerabilities and lifecycle challenges.

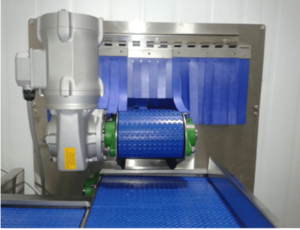

Recognizing the need for a new alternative, our manufacturing partner NORD set out to develop a solution to more affordably offer the protection and durability of stainless steel. The result is the nsd tupH Sealed Surface Conversion Solution. Unlike surface treatments, the base layer of nsd tupH is permanently bonded to the aluminum substrate, providing a powerful foundation for adhesion of the surface sealant. The treatment can be applied to gear units, smooth motors (up to IP69K), frequency inverters, and motor starters in washdown-optimized aluminum housings.

nsd tupH vs. Stainless Steel

Like stainless steel, nsd tupH is incredibly effective against wear and corrosion. It’s also easy to clean and resistant to acids and alkalis. Even if it’s damaged, there’s no infiltration of corrosion. It’s suitable for any application where 300 series stainless steel would be used, as long as specs allow for an alternative.

While stainless steel retains heat leading to motor wear and safety risks, aluminum coated with nsd tupH actually dissipates heat quite quickly. This means fewer workplace safety hazards and a longer equipment lifecycle. In addition, aluminum is lighter than stainless steel which makes it easier to mount and maintain.

While providing virtually all the benefits of stainless steel and a few that can’t be matched, there is one major difference between aluminum equipment treated with nsd tupH Sealed Surface Conversion and equivalent stainless steel equipment: the price. nsd tupH treated aluminum is significantly more affordable that the stainless steel alternative that has long been the industry standard.

nsd tupH Sealed Surface Conversion vs. Surface Coated Aluminum

You’re Not Just a Number at NORD

Obviously this proprietary NORD technology presents game changing capabilities for many of Agilix Solutions’ manufacturing customers. But beyond the products themselves, NORD is among the best of the best in customer service. They have consistently come through in critical situations for our customers. They prioritize customer service, and it is evident in everything they do.

If you’ve been looking for a suitable and affordable alternative to stainless steel materials in your production equipment, there’s finally an answer for you. Reach out to your account manager today to learn more about the NORD nsd tupH Surface Conversion Solution. If you don’t currently have an Agilix Solutions account manager, your nearest branch location can connect you with the people and resources you need to learn more.